The ICON project Rainbow aims to gain more insight into the erosion of rotor blades due to precipitation and lightning, because erosion entails significant production losses. This should provide new opportunities for preventive maintenance and improved strategies for inspection, maintenance and repair.

Duration : 1 January 2021 – 31 December 2023

Context

Wind turbine blade degradation due to leading-edge erosion is a result of the impact fatigue caused by the impingement of airborne particles, and lightning strikes. This phenomenon is held responsible for a loss in productivity between €56 and 75 million a year across the European offshore wind energy sector. Although there have been many research projects already aiming to reduce these losses, further research is still needed to improve the monitoring solutions and predictions.

Objective

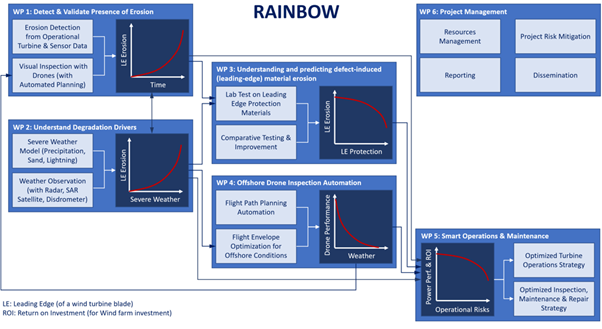

The Rainbow project will provide the offshore wind energy industry with an improved understanding of the drivers for leading edge erosion (LEE) of the offshore wind turbine blades, resulting in new predictive maintenance capabilities, and optimised strategies for inspection, maintenance & repair.

The project partners are committed to thorough monitoring of the turbines and energy yield on the one hand and automated inspection of rotor blades with drones on the other. Based on the results, coatings and other protective materials will be tested and validated under realistic North Sea conditions.

All this also makes it possible to better predict the life of wind turbines and better prepare and schedule inspection flights with drones. Eventually, this will result in a longer service life of the wind turbines and a drastic reduction in inspection, maintenance and repair costs. Better risk management of erosion and damage to turbine blades will also contribute to higher energy production and lower and more competitive energy prices.

Approach

In a first step, Rainbow will provide an insight in the correlation LEE versus time: an innovative combination of datasets from enhanced blade condition monitoring systems based on acoustic emissions and tower load measurements, performance monitoring by AI-aided SCADA data analysis and automated blade inspection by drones, will be used for the early detection of wind turbine performance degradation, caused by LEE.

Secondly, new multiscale weather models will generate predictive weather maps of wind speeds, precipitation erosion potential and lightning strike risks, identified as main drivers for LEE: they will define the correlation between blade integrity degradation and weather impact by precipitation and lightning. A quantitative characterization of the erosion drivers will allow to test and validate the blade coatings and Leading-Edge Protection (LEP) materials under realistic North Sea weather conditions, resulting in a classification of precipitation erosion. This will enable to predict their design-lifetime, in view of improving LEP durability and facilitate easier and more stable application, and more efficient maintenance and repair.

Weather forecast will also be used to stretch the flight envelope for drones, for optimal flight around idling wind turbines, for automated blade inspection thanks to machine-learning-based flight path planning. Finally, data-driven weather forecasting and nowcasting, combined with on-site monitoring of the weather-based erosion drivers, will pave the way towards LEE mitigating inspection, maintenance & repair strategies, thus leading to an increased lifetime of blades and a drastic reduction in maintenance & repair costs. Drone-based autonomous blade inspections with minimal weather risk and new diagnostic methods for early detection of blade damage will enable to reduce downtime and the costs of repairs. A classification for LEE and lightning strike damage can be transferred into operational risk assessment allowing for decision making.

Wind-farm operators (Norther and Otary) will implement the optimised strategies for monitoring and drone-based inspections into their operational procedures. This will result in an improved power performance and better return on investment. These optimised procedures, together with the required sensors and data acquisition systems, will be implemented gradually over all wind turbines in the wind farm, and will be extended to other windfarms as well. Better risk management of blade degradation will contribute to lower and more competitive energy prices.

SABCA, as specialist in aerospace systems, will contribute to the development of automated drone-based inspection flights. For SABCA, this research project will introduce new harsh weather operation capabilities and new functionalities for their drone technology platform. This innovation will provide SABCA a competitive advantage to promote itself in the international offshore inspection market.

ENGIE Laborelec, provider of technical services to the offshore (and onshore) wind farm operators, will increase its expertise on both the detection and root cause identification of blade degradation phenomena and overall WT underperformance, thus enhancing its inspection and root cause analysis services, which is an expanding activity along with the worldwide expansion of (offshore) wind. This expertise is also exported internationally, contributing to the affirmation that Flanders is a pioneer in offshore wind. The better technical services in their turn will lead to less downtime and better operational strategies to avoid damages.

References

ICON Rainbow

Partners

Otary, Norther, Engie Laborelec, Vrije Universiteit Brussel (VUB), Sirris and SABCA

Coordinator: VKI – Von Karman Institute of Technology

Financing

Total Budget: €3 952 569 (€2 217 850 subsidy)

Funded by VLAIO (via Blauwe Cluster and SIM)