Introduction

- SuperSized 4.0 - Smart O&M for a fleet of SuperSized wind turbines in Industry 4.0 context

- Number of Partners: 7

- Coordinator: Vrije Universiteit Brussel

- Start Date 01/01/2020

- Duration: 3 Years

- Total Budget: €2.420.645

- Funded by The Blue Cluster

SuperSized 4.0 Consortium Partners

Project Context

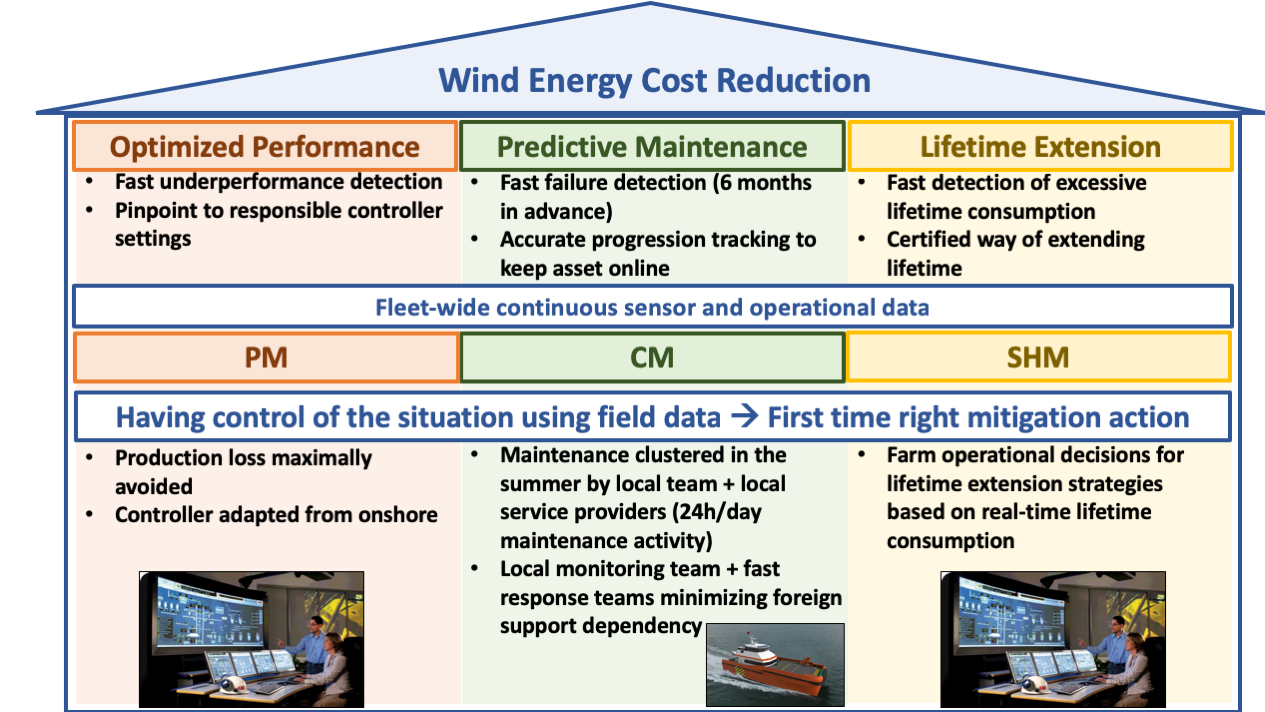

A new generation of wind turbines with power output above 8MW is currently being installed offshore. These machines are continuously upscaled to higher power output for the same machine. In Flanders, we are at the forefront with two farms: Norther (8.5MW machines) and Northwester 2 (9.5MW machines, for 2020). For such big machines the impact of stand-still of a single machine on the profitability of the farm is substantial given its high percentage in the total farm power output. At the same time there is tremendous pressure on the price of wind energy. Zero subsidy bids are getting more and more common. Thus, both our developers and our service providers need to change the way they perform O&M. This is only possible with a smart O&M approach avoiding production loss from underperformance and centred around predictive maintenance. Moreover, lifetime extension is needed to extend the profitable usage period of the machine. This not only positively influences the business case but also allows to keep turbines longer online while new ones are constructed. The latter accelerates the achievement of high wind penetration percentages in the energy mix to meet the renewable energy targets set for Flanders.

Project Description

We target an integrated methodology capable of assessing the risks for long-term underperformance, downtime due to failure and excessive lifetime consumption. The key to realize these goals is the development of innovative methods for monitoring based on continuous data from the fleet of turbines. Since historical data is scarce for these new machines, we rather use machine similarity to detect abnormalities. Three monitoring strategies are in focus: performance monitoring (PM), condition monitoring (CM) of the turbine, and structural health monitoring (SHM) of the foundation. Fleet-data originates from combining Fast SCADA, existing CM and SHM data with new extensive instrumentation on a limited number of turbines combined with a limited setup of IoT-based sensors additionally installed on all turbines in the fleet and connected through 5G. Not a single turbine, but the entire farm and even fleet are thus in focus both for instrumentation and methodologies. We aim to bring underperformance and failure detection methods beyond the state-of-the-art by exchanging monitoring features between similar turbines in the fleet rather than to focus on individual machines.